Boring Bars

Home > Turning > Boring Bars

Boring Bars

BORING BAR

Features Reference Screw-on System Boring Bar Internal Threading Boring Bar Double Clamp System Boring Bar

Central coolant

- High Rigid SKD61 material.

- Central coolant system.

- Strengthen the cooling and chip removal effect.

- Improve insert processing life effectively.

Carbide shank

- All carbide material.

- Increase the rigidity of the tool.

- Suppress vibration during processing.

- Improve machining accuracy with good surface roughness.

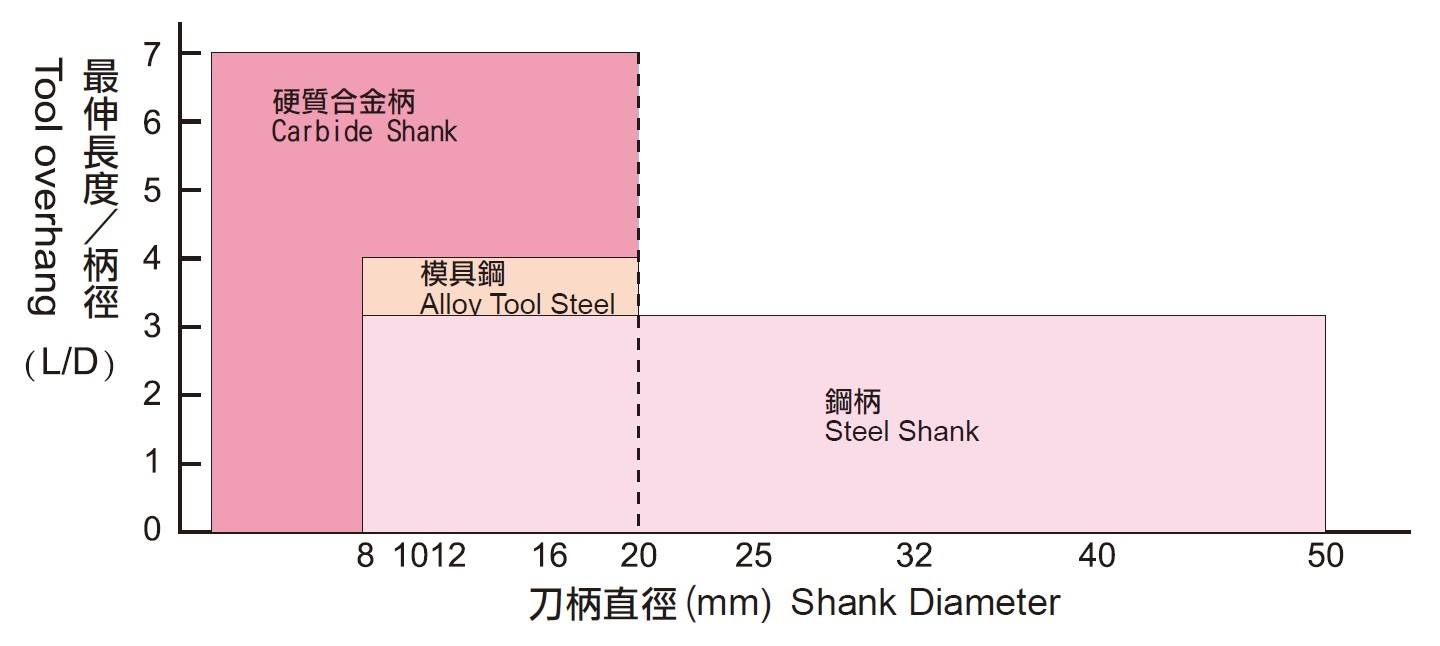

Application range by shank type

- Deep hole drilling of L/D = 6 with work diameters of 32mm and above.

- Negative inserts reduce unit price per corner.

- Combinable with a wide range of chipbreakers for use in everything from rough cutting to finishing.

Cutting Speed Vc=20~200m/min, Depth of cut ap=0.1~2.0mm, Feed Rate f=0.1~0.3mm/rev

*Actual amount of overhang may differ according to work material, tool shape, and machining conditions.

Quadruple Shack Resistance Boring Bar Series-Alloy tool steel

- High Rigid SKD61 shank.

- Four times tool overhang with vibration resistance capability.

Improve machining accuracy with good surface roughness